OBOGS Monitoring

Leave a CommentAircrew hypoxia warning times can be reduced by perfecting laser diode absorption spectroscopy oxygen sensors for OBOGS monitoring.

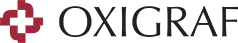

The onboard oxygen generating system(OBOGS) is an alternative to liquid oxygen (LOX). When compared to a LOX system, the OBOGS has several advantages. First, it’s availability may be as high as 99 percent. There is no requirement for depot-level maintenance. The OBOGS has no daily service requirements, and scheduled preventive maintenance occurs at 2,000 hours. Incorporation of the OBOGS eliminates the need to store and transport LOX. Additionally, it eliminates the need for LOX support equipment. The potential for accidents related to LOX and high-pressure gases is greatly reduced. The basic components of the OBOGS are the concentrator, oxygen monitor, and oxygen breathing regulator. The concentrator produces an oxygen-rich gas by processing engine bleed air through two sieve beds. The oxygen monitor senses the partial pressure of the gas and, if necessary, provides a low-pressure warning to the pilot. The oxygen regulator is a positive pressure regulator.

Pilot Hypoxia:

- Pilot hypoxia can result in impaired judgment, loss of aircraft, and loss of aircrew.

- 22 aircrew hypoxia reports investigated by NAWCAD over 2 years.

- F/A 18C Class A mishap, May 2001, loss of pilot/aircraft, $30M cost of aircraft and site cleanup.

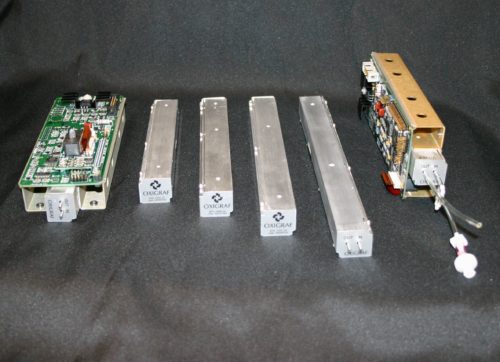

Oxigraf Fast Responding Oxygen Sensors:

- Reliable VCSELs now make laser diode oxygen sensors viable for air crew OBOGS monitors.

- Effort can be combined with OBOGS flow/pressure monitor for integrated pilot “dry mask” warning or backup system.

- LD Sensor fast enough to monitor gas composition blender systems.

Please download your On-Board Oxygen Generating System (OBOGS) Monitoring Application Note (pdf)

Oxygen Depletion Calculator

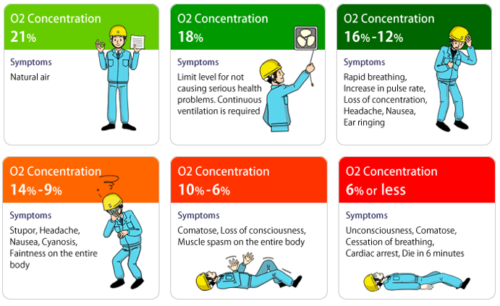

Leave a CommentThe calculation of percentage of oxygen in the air after the evaporation of a volume of liquefied gas – nitrogen or solid CO2 in a confined space.

- Calculate the volume (Vr m3) of the confined space.

- Calculate the volume of the released gas (Vg) by multiplying the volume of the liquid nitrogen (in liters) or weight of solid carbon dioxide (in Kg) by the expansion ratio of LN (.682) or the inverse density of CO2 (.552 m3/Kg).

- Calculate the volume of available oxygen (Vo m3) as 0.2095*(Vr-Vg).

- Calculate the % oxygen available to breathe as 100*Vo/Vr.