Category Archive: Product News

An On-Board Inert Gas Generation (OBIGG) system is now mandatory for many civilian and military aircraft to prevent the buildup of explosive conditions in fuel tanks by generating Nitrogen Enriched Air (NEA) to lower the oxygen content in the fuel tank headspace or ullage. Oxigraf provides a complete system for validating the performance of your OBIGG system.

The Oxigraf O2N2 oxygen analyzer characterizes the performance of an OBIGG system over an entire flight profile from takeoff, climb, cruise, and descent by measuring the oxygen concentration at multiple sites in the fuel tanks every 16 seconds.

The O2N2 analyzer is a specialized instrument evolved from Oxigraf oxygen analyzers commonly used for medical, scientific, and industrial process and safety applications. The patented laser diode absorption spectroscopy technology employed by Oxigraf is a natural fit for analyzing oxygen concentrations in a Jet-A fuel-air mixture as only light comes in contact with the gas sample, and the gas sample is maintained at a low temperature. The sensor responds in milliseconds, has no cross sensitivity to other gases, corrects automatically for changes in temperature and pressure, measures quickly over a wide dynamic range, and is insensitive to vibration.

The aircraft OBIGG validation system is comprised of several rack mount Oxigraf O2N2 oxygen analyzers mounted in a rugged rack system along with manual cut-off valves, regulators, purge and calibration gas supplies, and a laptop computer with the OxiFTE system control and data logging software. Fuel tank sample kits with float valves and tubing to sample locations complete an installation.

Additionally, the system has features to mitigate risks of escape of the sample gas, such as monitored nitrogen purging of the electronics enclosure. The OBIGG test system also features float valves at the fuel sample point to prevent ingestion of fuel at the sample location. Manual shut-off valves and test ports a low total system validation and operator intervention if necessary to remove the analyzers from contact with the fuel system.

The number of O2N2 analyzers in a system depends on the number of sample points required in the fuel tank system to be monitored, with each O2N2 analyzer having four (4) sample channels. The example system shown below is comprised of twelve (12) channels mounted in an 18U chassis with the other parts of the system. Oxigraf can provide standard 12U and 18U chassis along with custom racks as required for the application.

Please download your Oxigraf O2N2 OBIGGS Validation Brochure (pdf).

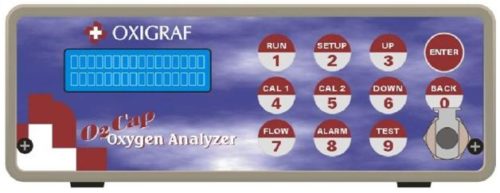

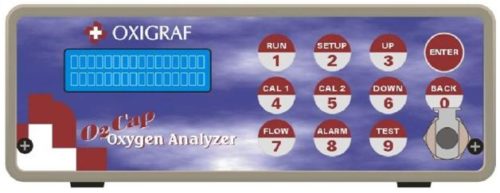

Model O2Cap Oxygen/CO2 Analyzer for Capnography:

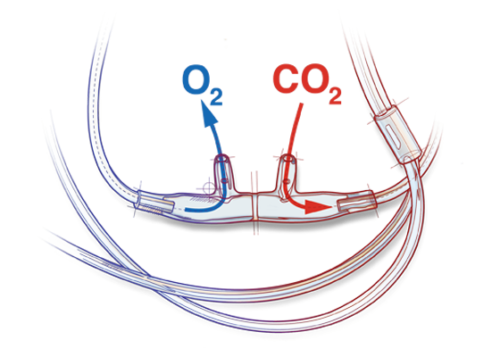

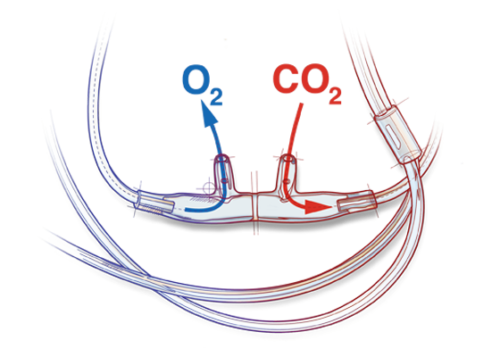

Monitoring of the concentration or partial pressure of oxygen and carbon dioxide (CO2) in respiratory gases requires fast response without overshoot. The Oxigraf Oxygen/CO2 Analyzers respond in less than a second. Electrochemical sensors may incorporate long averaging times, 20 or more seconds, for large, abrupt changes in oxygen concentration. Laser diode technology offers short response times to meet your capnographic requirements. The O2Cap family integrates an Oxigraf oxygen sensor with a NDIR CO2 sensor for dual gas measurements for research, medical and laboratory measurements.

The Oxigraf O2Cap may be the O2/CO2 Analyzer you need:

- Long life sensor, laser diode based sensor has a 10-year lifetime, does not require periodic replacement.

- Fast response time, unit will respond to abrupt changes in O2 level in seconds.

- NO errors due to vibration and movement

- NO errors due to temperature changes

- NO errors due to changes in barometric pressure

- Accurately displays O2 levels for measuring 5-100% oxygen concentrations and 0 to 10% CO2

Oxigraf works with clients across a wide range of industries to address their unique analyzing needs. Recently, for instance, we helped a client who was looking for a way to perform capnography tests with fast breath by breath measurement. The detailed case study is outlined below.

The Problem:

This client was looking for a way to measure and display the oxygen and CO2 concentrations in a gas sample drawn through the instrument. The company turned to Oxigraf for a reliable capnography solution.

The Solution:

The Oxigraf O2Cap is an analyzer that integrates a gas sampling system with sensors to measure and display the concentrations of oxygen and carbon dioxide in a sample as the percentage of a gas in the sample by volume. This method of expressing the concentration of a gas in a sample is also known as the percent volume fraction. In addition to the sampling and sensing systems in the O2Cap, the unit has a fluorescent display used for programming the unit and observing measurements, a keypad for programming the unit’s operation and calibration, and analog outputs that allow the unit to be connected to data recording units like the OxiSoft.

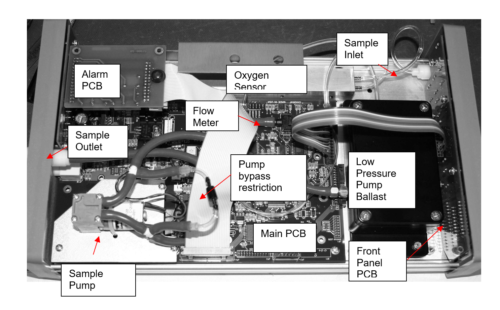

When measuring the concentrations of oxygen and carbon dioxide in a gas, a sample is pumped from the input port on the front panel of the O2Cap, through the sample cell, and out an exhaust port on the back panel of the unit. Gas samples are drawn into the unit through an external filter on the input port that protects the sensors from contamination and through Nafion tubing on the filter that removes moisture from the samples that would affect the measurements and the unit’s calibration. The oxygen concentration of the gas in the sample cell is measured using laser diode absorption technology. The laser diode in the oxygen sensor produces light at a wavelength (760 nanometers) that is absorbed by oxygen. The light passes through the gas pumped into the sample cell and onto the surface of a detector.

The output of the sensor is inversely proportional to the concentration of oxygen in the sample because the amount of light reaching the detector decreases as the concentration of oxygen in the sample increases. The O2Cap has a very fast response time that enables breath to breath analysis of gas concentrations because the unit analyzes the gas sample every 10 milliseconds, or 100 times per second. During each measurement interval, the analyzer is zeroed automatically by electronic tuning of the laser to a wavelength not absorbed by oxygen.

The Oxigraf laser diode oxygen analyzer has a very long life span — especially compared to other options on the market — and requires no periodic replacement or servicing.

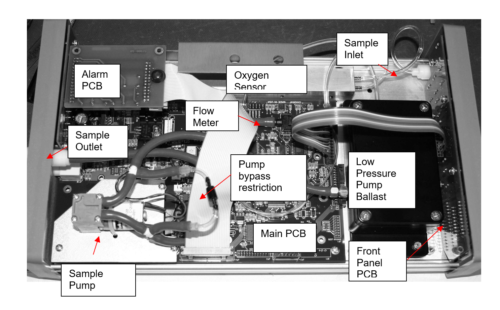

The Oxigraf Model O2Cap (AL) oxygen analyzer is a diverting oxygen monitor. Gas may be flowed under pressure with the sample pump off or on. The major components, pneumatic circuit, and flow path are shown in the block diagram above.

The Result:

The client’s problem was easily resolved with the use of our O2Cap analyzer model, which allowed for an accuracy of +/-0.2%. This client was very pleased with the system we provided and has since spread the word about our product line and capabilities to other customers in the medical industry.

The O2Cap gas analyzer is calibrated at the factory and is ready to take measurements. Just connect the source of the gas sample to the gas analyzer with the proper connections and press the RUN key.

The model O2Cap and O2CapB have luer type front panel gas sample input fitting for research applications. The model O2CapD have CPC O-Ring quick connect gas sample fittings for industrial applications.

All of the Model O2Cap, O2CapB and O2CapD include a sampling pump that will draw a sample from atmospheric pressure; with an external flow control valve, it will accommodate pressurized gas up to 1.3 psig (17 psia or 120 kPa).

An optional gas sampling valve allows the pump to draw a sample for a programmable number of seconds. This feature is useful for sampling from Modified Air Packaging (MAP).

Oxigraf O2Cap Oxygen/CO2 Features:

- Internal Sampling Pump.

- Relay contacts can be used to control external equipment.

- Relay contacts are Form C (SPDT), 5 A 250 VAC rating.

- Analog 4 to 20 mA, analog 0 to 1 VDC, and digital RS-232 outputs. Visual, audible, and remote alarms for Low O2, High O2, Low Flow and System Check.

- Samples and displays oxygen from 5 to 100% without range switching.

- Calibrates electronically using 10%O2/5% CO2 and 100% O2 cal gases.

- Electronic flow meter and display included.

- Front panel CPC-Quick connect fitting.

- Fast Response (< 1 sec) for prompt analysis.

- Pressure and temperature correction automatical

- No false oxygen readings with Ar, H2O, CO2, CO, or hydrocarbons.

- Rugged laser diode absorption spectroscopy oxygen analysis.

- Measures at low flows of 50 to 250 ml/min, conserving product gas.

Learn More:

Oxigraf has over 20 years of experience producing laser gas sensors and instruments and is the leading manufacturer of laser absorption spectroscopy sensors for oxygen gas measurement and analysis. Oxigraf O2iM Oxygen Safety Monitors have been widely adapted in hundreds of facilities since 2004, replacing a wide range of less reliable electrochemical sensors. Oxigraf O2 and CO2 sensors have been widely adapted by OEM manufacturers of medical respiratory gas monitors in order to measure breath waveforms, end-tidal gas values, anaerobic thresholds, VO2 max, and non-invasive cardiac outputs. For more information on our sensors, or to speak with an expert about your specific monitoring needs, contact the team today.

Please download your Oxigraf Case Study: Oxygen/CO2 Analyzer for Capnography (pdf)

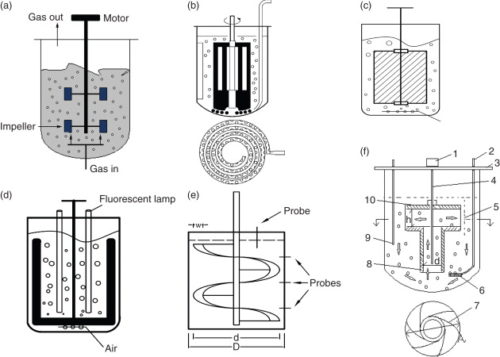

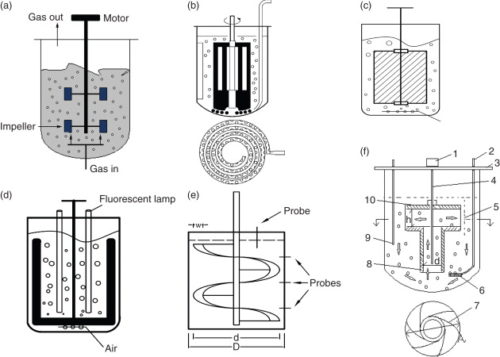

Fast Gas Analyzer for Bio-Physical Applications and Bioreactors

Based on the Oxigraf Model O2Cap Oxygen and CO2 analyzer, the O2Bio is specifically designed to provide gas monitoring of Bioreactor headspace and off-gas streams. The unit will measure continuously from an off-gas vent or periodically via a gas sample valve to take small 10-15ml samples from the bioreactor headspace via keypad or digital interface control.

The O2Bio integrates an Oxigraf tunable diode laser (TDL) oxygen sensor and a non-dispersive infrared (NDIR) CO2 sensor with a pump regulated gas sampling system. The analyzer features a bright vacuum fluorescent alphanumeric display (VFD), touch panel keypad, a rear 0-1VDC analog BNC output for O2 readings, rear terminal strip with limit detection relays and 4 – 20 mA analog outputs of O2 and CO2 reading, and a RS232 digital interface.

O2Bio – Bioreactor Off-Gas Monitoring of O2 and CO2

All inputs and outputs are CPC quick connect fittings with O-ring seals. Gas Inlet and Outlet with Swagelok or Luer fittings can be provided optionally.

The Oxigraf sensor uses laser diode absorption technology to measure oxygen concentration in the gas sample. A laser diode produces light in the visible spectrum at 760 nanometers. Light at this wavelength is absorbed by oxygen. To analyze oxygen the laser beam is focused through the sample gas onto a detector. Oxygen concentration is inversely proportional to the amount of light reaching the detector. An analysis is made every 10 ms.

The analyzer automatically zeroes at each measurement interval by electronically tuning the laser to oxygen non-absorption wavelength. CO2 is measured using a NDIR based accessory sensor and integrated into our hardware.

Oxygen measurements are made independent of sample pressure, gas temperature, and (in XC mode) other gases including Ar, He, H2, CO2 and H2O. Gases other than oxygen will not affect the measurement except for their dilution effect on the gas mixture.

APPLICATIONS:

- Fast Gas Analysis of: Oxygen and CO2

- Overlay and Sparge Gas Controller for Bioreactors

- Microbial Systems & Biofuel Development

- Biomass Growth Rate and Substrate Consumption Monitoring

- Anaerobic Fermentation

- Stem Cell & Mammalian Cell Cultures

Gas Sampling and Valve Control:

The O2Bio/O2Bio-B Analyzers are specifically designed to provide gas monitoring of Bioreactor headspace and off-gas streams. The unit will measure continuously from an off-gas vent or periodically via a gas sample valve to take small 10-15ml samples from the bioreactor headspace via keypad or digital interface control.

This Oxigraf analyzer is equipped with a solenoid sampling valve with 1 ms response time enabling sampling of very small sample volumes.

PERFORMANCE SPECIFICATIONS:

- Range: 0 to 10% CO2; 5 to 100% Oxygen

- Resolution: 0.1% in 0 to 100% O2 range; 0.01% in 0 to 10% CO2 range

- Sample Flow: 50 to 250 ml/min pump on; 50 to 500 ml/min pump off.

- Response Time: Approximately 150 ms @ 250 ml/min flow (depending on electronic filter setting).

- Valve Response: 1 ms for Solenoid sampling valve

- Stability (4hrs): ±0.2%.CO2 after 5 minute warm up; ±0.3%oxygen in XC mode, ±0.1% in oxygen LN mode

- Dimensions: 7.5 x 3.0 x 14.0 inches (190 x 76 x 356 mm) WxHxD

- Weight: 7 pounds (3.2 kg)

- Warranty: One year

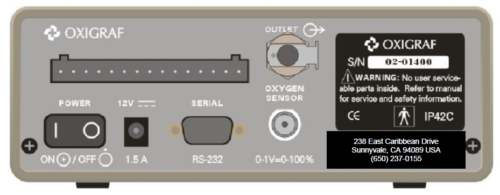

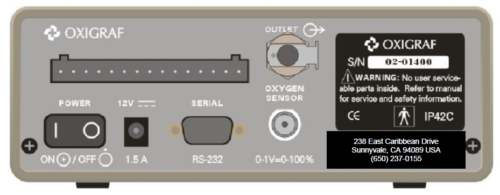

Back Panel Interface:

Back Panel O2Bio with rear terminal strip with limit detection relays:

The power on/off switch (Press “I” for on, “O” for off), 12 VDC power input jack, service interface, terminal block interface, and a gas outlet port are located on the instrument back panel. Power is supplied by an external 12 Volt, 2 Amp CSA Level 3 power supply. The RS – 232 port is provided to interface with a computer.

Calibration Kit:

Calibration Kit includes certified concentration gas cylinders, preset flow regulators, and tubing with connectors which mate with the analyzer and gas cylinder. The tubing assembly includes a fine flow needle valve. Instrumentation grade, certified calibration gas meets FDA standards for USP oxygen analyzers. Each cylinder provides approximately 3 months of daily calibrations. Calibration gas is shipped direct from the gas supplier.

Please download your Oxigraf Model O2Bio/O2Bio-B Oxygen and CO2 Gas Analyzers Brochure (pdf)

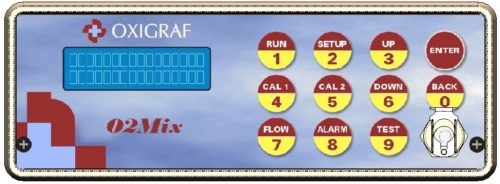

Fast Gas Mixer Overlay and Sparge Gas Controller for Bioreactors

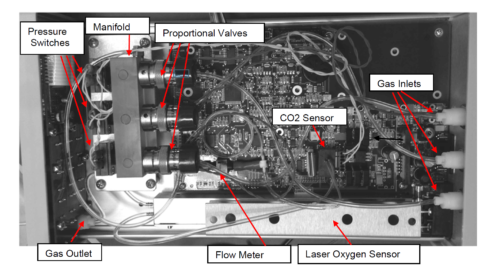

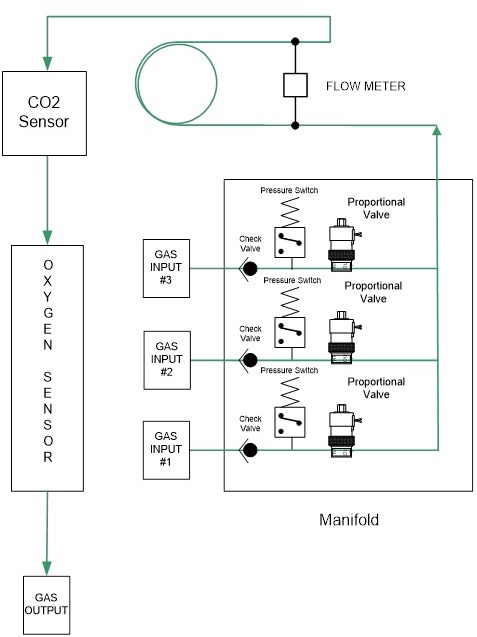

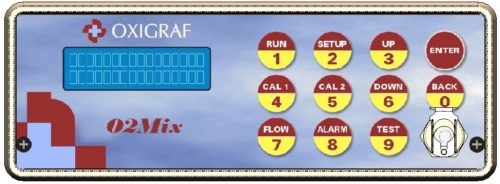

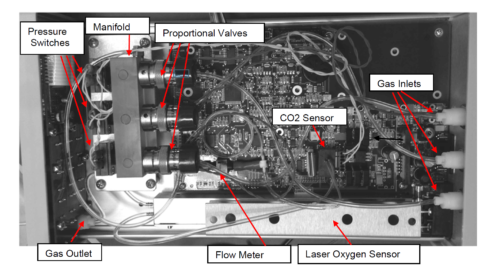

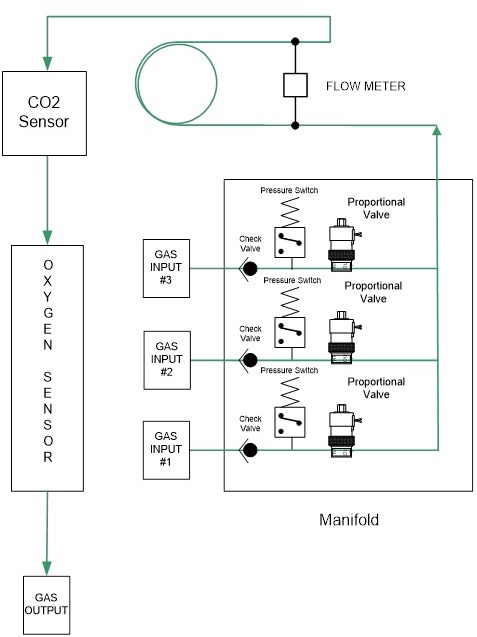

The Model O2MIX gas mixer measures the oxygen and CO2 concentration in a gas sample inside instrument and uses this as feedback to control three (3) proportional valves to blend gasses from the three (3) inputs to a single output. The product uses feedback from actual gas measurements as a control point and different mixture and blends of gasses can be used to feed three (3) inputs for mixing. In normal operation the O2MIX is designed to accept Oxygen, Nitrogen (or Compressed “Air”) and CO2 as inputs, and a single blended output of a programmed mixture is produced by the unit to feed a Bioreactor.

The Oxigraf sensor uses laser diode absorption technology to measure oxygen concentration in the gas sample. A laser diode produces light in the visible spectrum at 760 nanometers. Light at this wavelength is absorbed by oxygen. To analyze oxygen the laser beam is focused through the sample gas onto a detector. Oxygen concentration is inversely proportional to the amount of light reaching the detector. An analysis is made every 10 ms.

The analyzer automatically zeroes at each measurement interval by electronically tuning the laser to oxygen non-absorption wave length. CO2 is measured using a NDIR based accessory sensor and integrated into our hardware.

Oxygen measurements are made independent of sample pressure, gas temperature, and (in XC mode) other gases including Ar, He, H2, CO2 and H2O. Gases other than oxygen will not affect the measurement except for their dilution effect on the gas mixture.

Step-Up from other Mixing Technologies:

- Accurately mixes O2 and/or CO2 with air or nitrogen by measuring the gas concentration rather than by estimating mixtures from flow measurements.

- Accurately controls flow independently.

- O2 Range: 21 to 75%. Accuracy: + – 0.3% using tunable diode laser absorption.

- CO2 Range: 0 to 10%. Accuracy: + – 0.2% using non-dispersive infrared.

- Flow: 100 to 700 ml/min.

- Long life sensor, laser diode based sensor has a 10 year lifetime, does not require periodic replacement.

The O2 Mix integrates an Oxigraf oxygen sensor with a gas sampling system, vacuum fluorescent alphanumeric display (VFD), keypad, limit, a CO2 sensor, a Mixer element utilizing three (3) proportional valves on an integrated manifold, and a RS232 link with Oxigraf communication protocol. Three (3) gas inputs are supplied for O2, Nitrogen (or air) and CO2 and mixed using the feedback of the O2 and CO2 sensors to a single front panel outlet. All inputs and outputs are CPC quick connect fittings with O-ring seals.

APPLICATIONS:

- Gas Mixing of: O2, Nitrogen (or air) and CO2

- Overlay and Sparge Gas Controller for Bioreactors

- Microbial Systems & Biofuel Development

- Anaerobic Fermentation

- Stem Cell & Mammalian Cell Cultures

O2MIX Flow Diagram:

PERFORMANCE SPECIFICATIONS:

- Range: 0 to 10% CO2; 21 to 75% Oxygen

- Resolution: 0.1% in 21 to 75% O2 range; 0.01% in 0 to 10% CO2 range

- Sample Flow: 100 to 700 ml/min adjustable.

- Response Time: Mixing gasses settle in several seconds

- Stability (4hrs): ±0.2%.CO2 after 5 minute warm up; ±0.3%oxygen in XC mode, ±0.1% in oxygen LN mode

- Dimensions: 7.5 x 3.0 x 14.0 inches (190 x 76 x 356 mm) WxHxD

- Weight: 7 pounds (3.2 kg)

- Warranty: One year

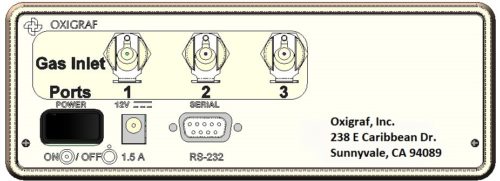

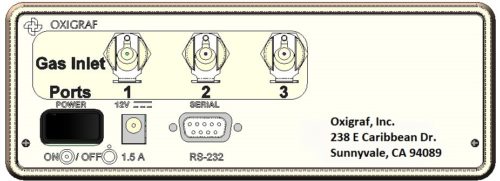

Back Panel Interface:

Three (3) gas inlet ports are located on the rear panel of the unit. Input 1 is for Oxygen or calibration gas. Input 2 is for compressed dry air (CDA) or Nitrogen (N2) gas. Input 3 is for CO2 gas. When mixing just O2 and N2, input 3 should be “tee-d” to Input 2 to pressurize the switch on input 3 to prevent a false low gas condition on this input. All the inlets are CPC quick connect fittings.

The power on/off switch (Press “I” for on, “O” for off), 12 VDC power input jack, RS-232 interface 9-pin DIN connector, and three (3) gas inlet ports are located on the instrument back panel. Power is supplied by an external 12 volt, 2 amp CSA Level 3 power supply.

The RS – 232 port is provided to interface with a computer.

Calibration Kit:

Calibration Kit includes certified concentration gas cylinders, preset flow regulators, and tubing with connectors which mate with the analyzer and gas cylinder. The tubing assembly includes a fine flow needle valve. Instrumentation grade, certified calibration gas meets FDA standards for USP oxygen analyzers. Each cylinder provides approximately 3 months of daily calibrations. Calibration gas is shipped direct from the gas supplier.

Please download your Oxigraf Model O2MIX Fast Gas Mixer Overlay and Sparge Gas Controller for Bioreactors Brochure (pdf)

A cardiopulmonary exercise test (CPET) is an evaluation of the cardiopulmonary system.

Physical exercise requires the interaction of the physiologic mechanisms that enable the cardiovascular and respiratory systems to support the energy demands of the contracting muscles. Both systems are consequently stressed during exercise. Their ability to respond adequately to this stress is a measure of their physiologic competence.

- Studies are performed under the direction of the cardiology and pulmonary divisions

- Emphasis of testing may be influenced by the requesting division

- Cardiac patients have more detailed electrocardiogram (ECG)/hemodynamic monitoring during testing

- Pulmonary patient studies may include bronchial provocation with exercise testing

- Exercise modalities

- Bicycle ergometer

- Treadmill

- Selection of modality and protocol are dependent upon the requesting physician, level of fitness and health, weight, age, and patient preference

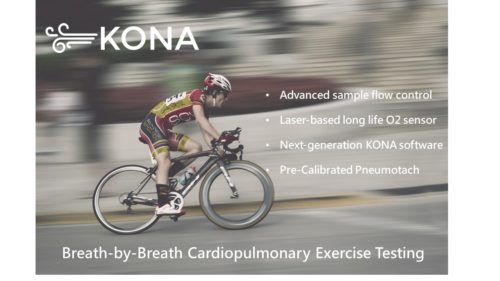

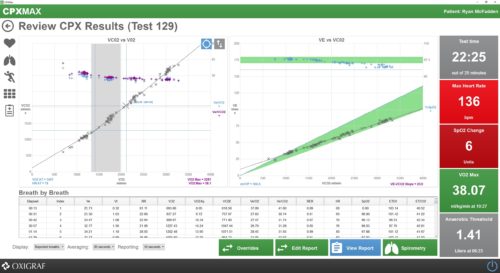

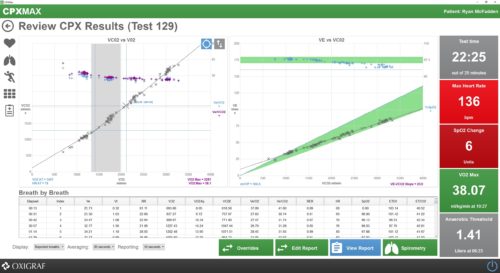

Model O2CPX – Cardiopulmonary Exercise Analyzer

The Model O2CPX is a table top analyzer used to monitor performance parameters during exercise testing. Breath-by-breath O2, CO2 and flow rate is measured precisely and accurately with internal sensors. Heart rate and pulse oximetry interfaces are compatible with Polar and Nonin accessories. Ambient temperature, humidity and barometric pressure is acquired for precise measurement correction. Our reliable solid state oxygen sensor does not require routine maintenance or factory calibration. Our O2CPX hardware easily collaborates with customer software solutions via USB interface.

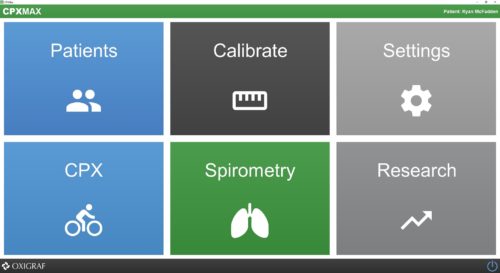

KONA Software Designed for The Model O2CPX

Next generation cardiopulmonary exercise testing screen, with interactive breath-by-breath validation:

- Visual test results viewer with custom charts and tabular breath-by-breath view.

- Automatic VO2 and anaerobic thresholds can be manually overridden.

- Custom reports including charts and key metrics.

- FVC spirometry comparison test and pre/post FVCcomparison test.

- Spirometry reports can be generated independently.

- Patient management section with demographic information.

- Easy calibrate screen. Pneumotachs are easily calibrated by entering a quick code.

- Automatic flow volume correction using built in, temperature, humidity and barometric pressure sensors.

- Oxygen saturation and polar heart rate input.

- Optional ECG stress-test integration.

- Optional multi-node test site version with shared relational database engine and support for 25+ test and review stations

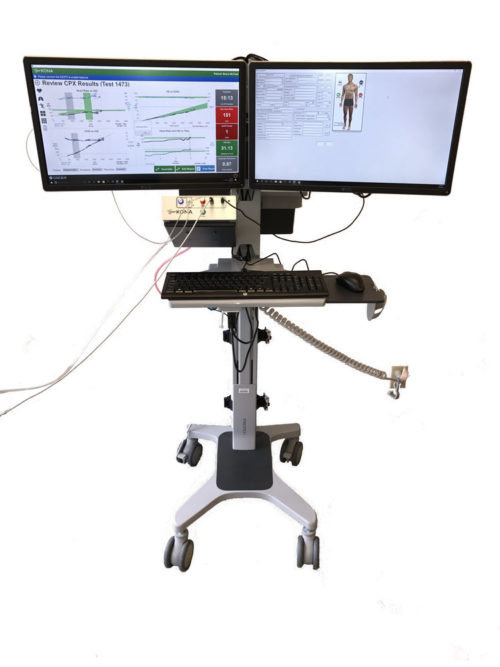

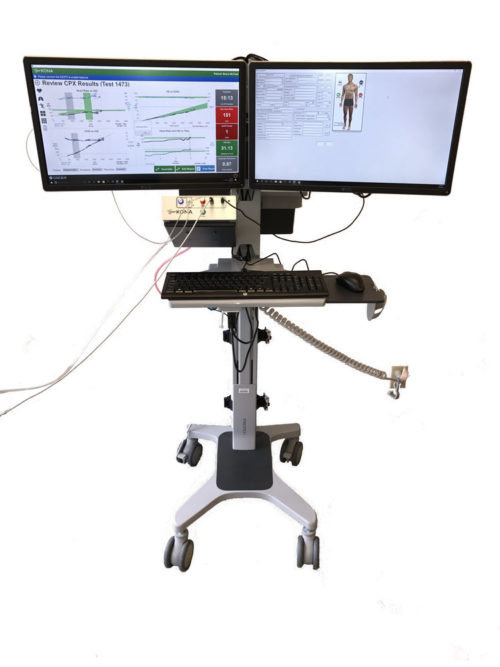

Ergotron System Cart

Ergotron Neo-flex computer cart with height adjustable monitor and work surface for standing and sitting situations.

Complete systems cart configuration with mounting for

- Oxigraf Model O2CPX Cardio-Pulmonary Exercise Test Analyzer mounting

- Single monitor (up to 42 inch) or dual monitor mounting for 22 inch displays

- Keyboard and Mouse work surface

- Integrated Intel NUC computer mounting

- Integrated power and cable routing

- Mounting for 500L calibration gas cylinder on rear

Please download your O2CPX analyzer brochure.

Please download your KONA Software brochure.

Please download your Ergotron Cart brochure.