Oxigraf Model O2MIX O2 and CO2 Gas Mixer

Fast Gas Mixer Overlay and Sparge Gas Controller for Bioreactors

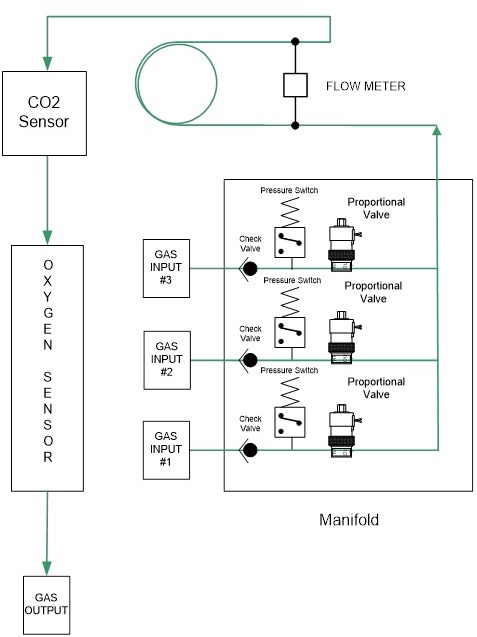

The Model O2MIX gas mixer measures the oxygen and CO2 concentration in a gas sample inside instrument and uses this as feedback to control three (3) proportional valves to blend gasses from the three (3) inputs to a single output. The product uses feedback from actual gas measurements as a control point and different mixture and blends of gasses can be used to feed three (3) inputs for mixing. In normal operation the O2MIX is designed to accept Oxygen, Nitrogen (or Compressed “Air”) and CO2 as inputs, and a single blended output of a programmed mixture is produced by the unit to feed a Bioreactor.

The Oxigraf sensor uses laser diode absorption technology to measure oxygen concentration in the gas sample. A laser diode produces light in the visible spectrum at 760 nanometers. Light at this wavelength is absorbed by oxygen. To analyze oxygen the laser beam is focused through the sample gas onto a detector. Oxygen concentration is inversely proportional to the amount of light reaching the detector. An analysis is made every 10 ms.

The analyzer automatically zeroes at each measurement interval by electronically tuning the laser to oxygen non-absorption wave length. CO2 is measured using a NDIR based accessory sensor and integrated into our hardware.

Oxygen measurements are made independent of sample pressure, gas temperature, and (in XC mode) other gases including Ar, He, H2, CO2 and H2O. Gases other than oxygen will not affect the measurement except for their dilution effect on the gas mixture.

Step-Up from other Mixing Technologies:

- Accurately mixes O2 and/or CO2 with air or nitrogen by measuring the gas concentration rather than by estimating mixtures from flow measurements.

- Accurately controls flow independently.

- O2 Range: 21 to 75%. Accuracy: + – 0.3% using tunable diode laser absorption.

- CO2 Range: 0 to 10%. Accuracy: + – 0.2% using non-dispersive infrared.

- Flow: 100 to 700 ml/min.

- Long life sensor, laser diode based sensor has a 10 year lifetime, does not require periodic replacement.

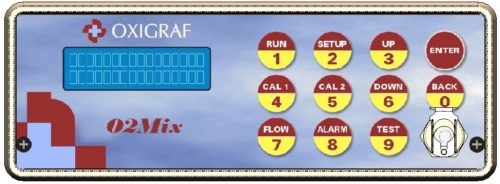

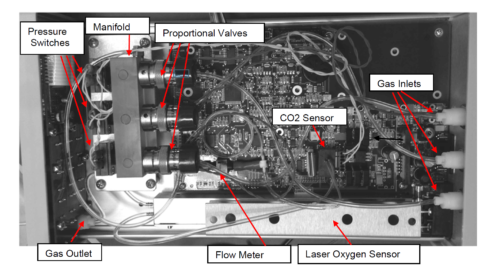

The O2 Mix integrates an Oxigraf oxygen sensor with a gas sampling system, vacuum fluorescent alphanumeric display (VFD), keypad, limit, a CO2 sensor, a Mixer element utilizing three (3) proportional valves on an integrated manifold, and a RS232 link with Oxigraf communication protocol. Three (3) gas inputs are supplied for O2, Nitrogen (or air) and CO2 and mixed using the feedback of the O2 and CO2 sensors to a single front panel outlet. All inputs and outputs are CPC quick connect fittings with O-ring seals.

APPLICATIONS:

- Gas Mixing of: O2, Nitrogen (or air) and CO2

- Overlay and Sparge Gas Controller for Bioreactors

- Microbial Systems & Biofuel Development

- Anaerobic Fermentation

- Stem Cell & Mammalian Cell Cultures

O2MIX Flow Diagram:

PERFORMANCE SPECIFICATIONS:

- Range: 0 to 10% CO2; 21 to 75% Oxygen

- Resolution: 21% in 0 to 75% O2 range; 0.01% in 0 to 10% CO2 range

- Sample Flow: 100 to 700 ml/min adjustable.

- Response Time: Mixing gasses settle in several seconds

- Stability (4hrs): ±0.2%.CO2 after 5 minute warm up; ±0.3%oxygen in XC mode, ±0.1% in oxygen LN mode

- Dimensions: 7.5 x 3.0 x 14.0 inches (190 x 76 x 356 mm) WxHxD

- Weight: 7 pounds (3.2 kg)

- Warranty: One year

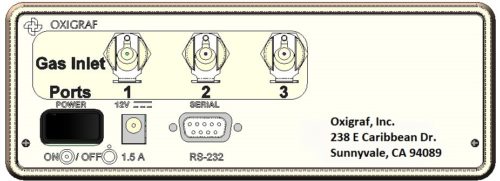

Back Panel Interface:

Three (3) gas inlet ports are located on the rear panel of the unit. Input 1 is for Oxygen or calibration gas. Input 2 is for compressed dry air (CDA) or Nitrogen (N2) gas. Input 3 is for CO2 gas. When mixing just O2 and N2, input 3 should be “tee-d” to Input 2 to pressurize the switch on input 3 to prevent a false low gas condition on this input. All the inlets are CPC quick connect fittings.

The power on/off switch (Press “I” for on, “O” for off), 12 VDC power input jack, RS-232 interface 9-pin DIN connector, and three (3) gas inlet ports are located on the instrument back panel. Power is supplied by an external 12 volt, 2 amp CSA Level 3 power supply.

The RS – 232 port is provided to interface with a computer.

Calibration Kit:

Calibration Kit includes certified concentration gas cylinders, preset flow regulators, and tubing with connectors which mate with the analyzer and gas cylinder. The tubing assembly includes a fine flow needle valve. Instrumentation grade, certified calibration gas meets FDA standards for USP oxygen analyzers. Each cylinder provides approximately 3 months of daily calibrations. Calibration gas is shipped direct from the gas supplier.

Please download your Oxigraf Model O2MIX Fast Gas Mixer Overlay and Sparge Gas Controller for Bioreactors Brochure (pdf)