Manufacturer of

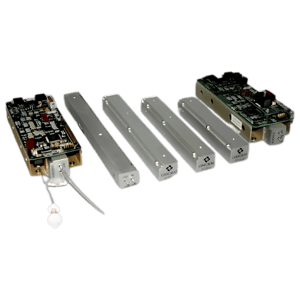

Laser Diode Oxygen Analyzers and Oxygen Sensors

Oxygen Deficiency Monitors

Oxygen Analyzers

Laboratory & Research

Industrial Process

Aerospace

OEM (Sensors)

Oxigraf. Precision-Crafted Oxygen Analysis and Monitoring

Oxigraf specializes in high-precision gas analyzers and integrated software for real-time gas monitoring and measurement, providing accurate and reliable data for safe, sustainable operations. Our field-tested detection equipment and cutting-edge software form a unified ecosystem to baseline assets, ensuring compliance and protecting both people and the environment. With over 30 years of hands-on experience, Oxigraf offers on-the-ground support, streamlining reporting to mitigate risk and promote sustainability.