Oxigraf Case Study: Linear Acceleration Tunnel Oxygen Deficiency Sensor

Leave a CommentThe Oxigraf team recently worked with a client to provide them with a reliable, high-quality linear acceleration tunnel oxygen deficiency sensor. A detailed case study is outlined below.

The Problem

A customer was in need of a reliable solution for sampling gas from remote locations in a tunnel in order to monitor equipment and personnel safety. During their operations, they were dealing with radiation hazards, which posed risks for electronics, and during maintenance periods, they were dealing with the presence of nitrogen and helium, which presented oxygen deficiency hazards. Oxygen deficiency in the workplace can lead to blackouts, cause falls, and present more serious health risks — some of which can be fatal. The Oxigraf team was brought in to help them eliminate the risk of oxygen depletion.

The Solution

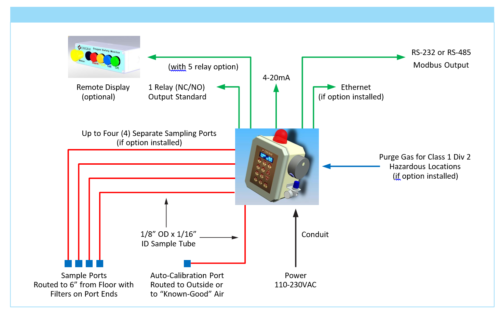

After assessing the clients’ unique needs, we opted to provide them with our Oxigraf Model O2iM, which has a high-flow pump option and allows for sampling from long distances. This sensor allows for continual monitoring of the clients’ tunnel atmosphere from a safe location, and provides local alarms and interfaces with sophisticated safety features to prevent hazards such as cryogenic spills, which can lead to rapid displacement of breathing air. Oxigraf’s top-of-the-line oxygen deficiency monitor is flexible and efficient, and provided the client with a reliable, immediate oxygen alarm for concentrations of less than 19.5%. It also eliminated the need for frequent recalibration or replacement of oxygen sensors, as well as the comprehensive, time-consuming maintenance often involved in sampling systems. The risk of false alarms and alarm failures was also eliminated.

This unique sensor features a rapid response time of less than a second. The transit time of the gas sample through the sampling tube may be 1 second per meter of sampling tube, and to respond within 5 seconds, an oxygen monitoring alarm with a 1-second response time can be placed within 4 meters of the potential hazard. The built-in pump draws gas remotely, allowing for these quick response times. In fact, we offer the best response speed/signal in the industry, and can add multiplexors (valving) in order to monitor four or more locations from over 100 feet away.

Additionally, this sensor is insensitive to movement, has auto-calibration for absolute accuracy, and includes options for multi-port and high-flow sampling. It also features a remote display and battery backup to allow for proper functioning during power interruptions. In addition, it can be fitted with a Z-Purge system, which allows the unit to be used in Class 1 Div 2 hazardous areas. The monitor includes a sampling pump, hydrophobic filter, and flow sensor, while the microprocessor controller maintains the flow at a constant value.

The Result

The customer compared our O2iM sensor to other O2 sensing solutions and determined that O2iM was “the champion,” allowing for reliable performance 24/7. They were especially impressed with the unique engineering of the “Pre-Fetch” high-flow pump option, which allows for the monitoring of distant sample locations while maintaining fast response times.

Typical O2iM Installation:

Learn More

Oxigraf has over 15 years of experience producing laser gas sensors and instruments, and is the leading manufacturer of laser absorption spectroscopy sensors for oxygen gas measurement and analysis. Oxigraf O2iM Oxygen Safety Monitors have been widely adapted in hundreds of facilities since 2004, replacing a wide range of less reliable electrochemical sensors. Oxigraf O2 and CO2 sensors, in particular, have been widely adapted by OEM manufacturers of medical respiratory gas monitors in order to measure breath waveforms, end-tidal gas values, anaerobic thresholds, VO2 maxs, and non-invasive cardiac outputs. For more information on our sensors, or to speak with an expert about your specific monitoring needs, contact the team today.

Please download your Oxigraf Case Study: Linear Acceleration Tunnel Oxygen Deficiency Sensor

2019 Holiday Schedule Update

Leave a Comment

Oxigraf Offices will be closed the following days during the 2019 holiday season:

- December 25, 2019 Closed for Christmas;

- January 1, 2020 Closed for New Years Day